Get Inquiry

Send an inquiry and get in touch

Confirming the Transaction

Video photos, confirm transaction

Acceptance of Transportation

On site acceptance, packing and transportation

Sorting Processing

Sort materials and process them by category

Grinding and Decomposition

Physical grinding, chemical decomposition

Purification and Recovery

Purification of materials, completion of recycling

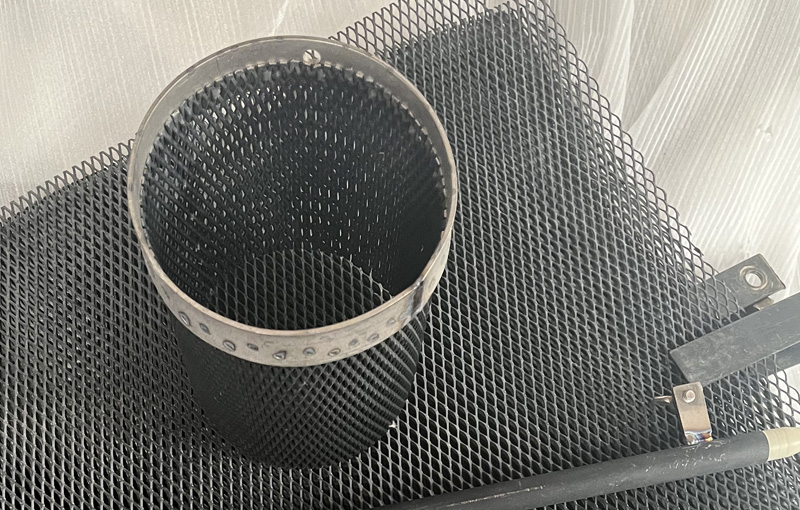

Hydrogen Production Equipment

An alkaline water electrolysis hydrogen production system mainly includes the alkaline electrolyzer body and the BOP (Balance of Plant) auxiliary system. Alkaline water electrolysis hydrogen production refers to the process of producing hydrogen by electrolyzing water in an alkaline electrolyte environment. The electrolyte is usually a potassium hydroxide (KOH) solution at about 31% concentration or a sodium hydroxide (NaOH) solution at 26.5% concentration.

The main body of the alkaline electrolyzer is assembled from parts like end plates, electrode plates, and electrodes. When producing hydrogen, water molecules inside the alkaline electrolyzer receive electrons at the cathode to form hydrogen gas and hydroxide ions (OH?). These hydroxide ions pass through a membrane to the anode. Under the applied voltage, they react to form oxygen gas and water. Nickel electrodes, nickel diaphragms, and sealing gaskets are key materials for alkaline electrolyzers. Among these, the nickel electrode is the main material DONGSHENG recycles and is one of the main precious metal materials in hydrogen production equipment.

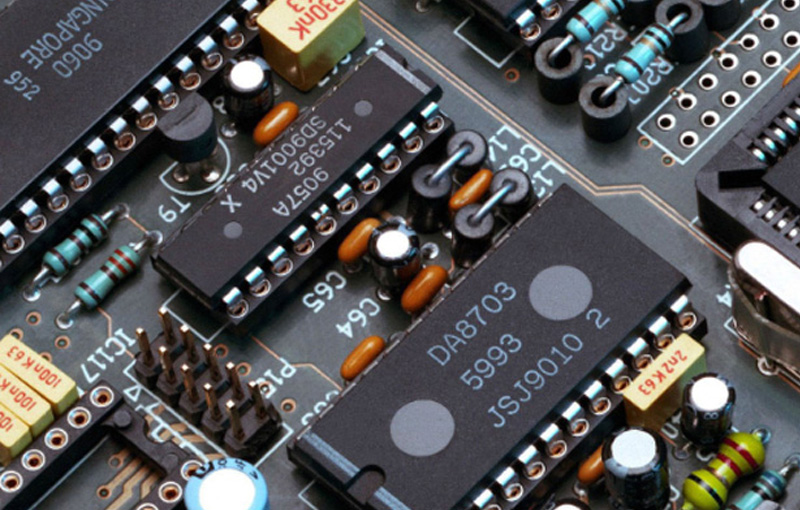

Typically, a pem electrolyzer has tens to hundreds of electrolysis cells. The pem electrolyzer is mainly made up of a proton exchange membrane (PEM), cathode/anode catalyst layers, gas diffusion layers (GDL), and bipolar plates. The hydrogen production process in a pem electrolyzer is generally: water enters through the bipolar plate into the gas diffusion layer and then reaches the proton exchange membrane. After applying current and voltage, the water splits into protons (H?) and oxygen ions (O2?). The oxygen ions release electrons to form oxygen gas, which is output through the anode tube. The protons pass through the proton membrane to the cathode, where they combine with electrons to form hydrogen gas, which is output through the cathode tube to a gas-liquid separator.

1, Alkaline electrolyzer has high and stable hydrogen production speed, service life up to 200,000 hours, suitable for large-scale hydrogen production, low cost.

2, Pem electrolyzer: Fastest start-up time. Because it operates in a highly acidic and oxidizing environment, this type of hydrogen production equipment must rely on precious metals like iridium, platinum, and titanium. Its hydrogen production cost is the highest of the three. Therefore, it is more suitable for small applications needing a quick response.

3, soec electrolyzer: Needs to work at high temperatures. Although its energy consumption for hydrogen production is the lowest, its hydrogen production speed and service life are not as high as the alkaline electrolyzer. Its investment and maintenance costs are also relatively high. Therefore, it is not well-suited for commercial applications.

Because hydrogen production equipment using pem electrolyzers as the core is smaller, lighter, and its precious metal parts have higher recycling value, DONGSHENG can provide customized professional recycling solutions for this type of equipment.