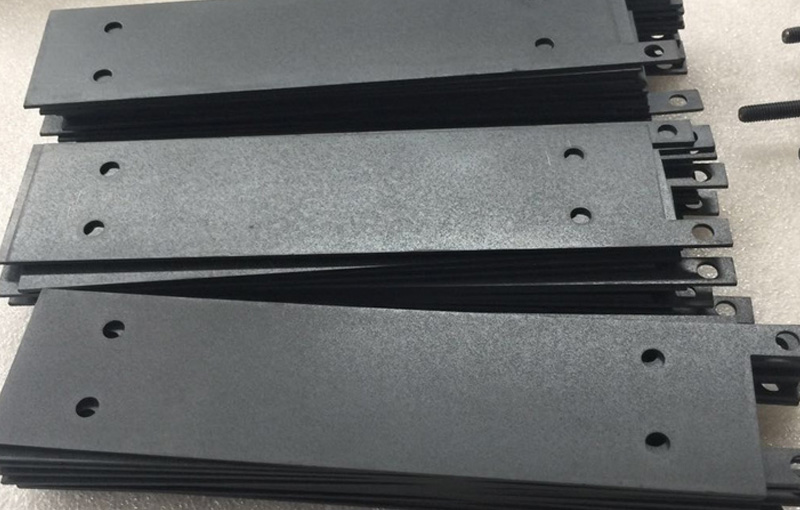

Titanium electrode products replace traditional graphite electrodes, avoiding pollution while increasing current efficiency by more than 95%. Due to the specialized nature of titanium electrodes, practitioners in the titanium electrode market prefer to classify titanium electrode products by their structural shape. For example, titanium electrode plates for industrial electrolyzers, titanium electrode grids for electrochemical reactors, and titanium electrode tubes for special electrolysis devices. The price of coated titanium electrode recycling is higher than that of pure titanium electrode recycling, and titanium electrode recycling plants also prefer coated titanium electrodes!

Advantages of Coated Titanium Electrode

Ordinary uncoated titanium electrodes have a low price but a short service life. Coated titanium electrodes are more expensive than ordinary titanium electrodes, but the service life is increased by more than 5 times. In order to reduce production costs, coated titanium electrodes are more expensive but more popular in the market. The recycling price of coated titanium electrodes is naturally higher!

1, chlor-alkali industry: used for electrolysis of table salt chlorine N117 type black titanium anode, current efficiency up to 92%, life is enhanced to 5 years;

2, electrolysis of water to produce hydrogen: in the proton exchange membrane electrolysis tanks, the use of composite anode hydrogen production rate ≥ 1.5 L / (cm2-h);

3, electroplating industry: platinum titanium anode to make the plating process of the current density up to 800 A/m2, the uniformity of plating layer ± 2% ;

4, environmental protection field: titanium electrode can degrade organic wastewater, COD removal rate is greater than 85%.

Titanium electrode using composite coating technology is the future development trend, can make titanium electrode product life cycle extended to more than 10 years. Although, the precious metal titanium is a rare resource and non-renewable! Fortunately, the innovation of titanium electrode recycling technology, so that the precious metal recycling rate increased to 95%.