Cemented carbide contains the hard-to-melt metal tungsten (cement carbide) and has high recycling value. Common recycled cemented carbide products include: cemented carbide cutting tools, cemented carbide drill bits, cemented carbide inserts, cemented carbide lathe tools, cemented carbide milling cutters, and cemented carbide tips. The CNC machining industry is the main source of DONGSHENG's cemented carbide recycling. This is because cemented carbide tools are essential for CNC precision machining.

Cemented Carbide Tool

Turning tools: Mostly use indexable cemented carbide lathe tools (cemented carbide tips). Milling tools: There are two main kinds: milling inserts with cemented carbide tips and solid cemented carbide milling cutters. Drilling tools: Also two main kinds: solid cemented carbide drill bits and drill bits with welded cemented carbide tips. Hole-making tools: Include cemented carbide reamers, boring tools, and taps. Sawing tools: Are metal circular saw blades and bandsaw blades with cemented carbide teeth tips.

Mining uses cemented carbide bits for rock drilling. Oil drilling also uses cemented carbide drill bit teeth;

Some wear-prone areas on molds use cemented carbide (for example: wire drawing dies, cold heading dies, stamping dies, and forming dies);

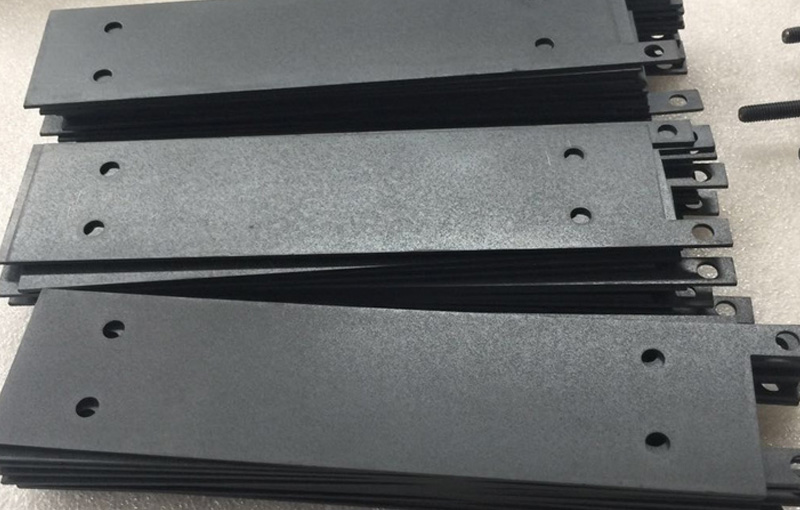

Cemented carbide structural parts include sealing rings, nozzles, guide rails, rolls, and top hammers.

To make tools last longer and reduce costs, some woodworking tools use cemented carbide. Examples: planer blades, router bits, and saw blades. Construction and road engineering face very hard and complex working conditions. Commonly used cemented carbide tools include: cemented carbide cutters for road milling, cemented carbide tools for tunnel boring machines (TBM), and cemented carbide drill bits for pile driving.