Scrap metal recycle is an important business of industrial waste treatment plant. Industrial waste treatment plants can process waste liquids and plating sludge from the electroplating industry containing heavy metals such as nickel, chromium and copper. They often distribute the more valuable titanium anodes and nickel cathodes to precious metal recycling companies for disposal! Industrial waste treatment plants are proficient in membrane separation technology, electrolysis and chemical precipitation, through which heavy metals are extracted from industrial waste streams.The industrial waste treatment plant of DONGSHENG is more specialized in the regeneration of titanium anodes, which separates the failed coating of titanium anodes from the titanium matrix, which can be reused, thus reducing the market demand for titanium mining and reducing carbon emissions.

Industrial Solid Waste Treatment

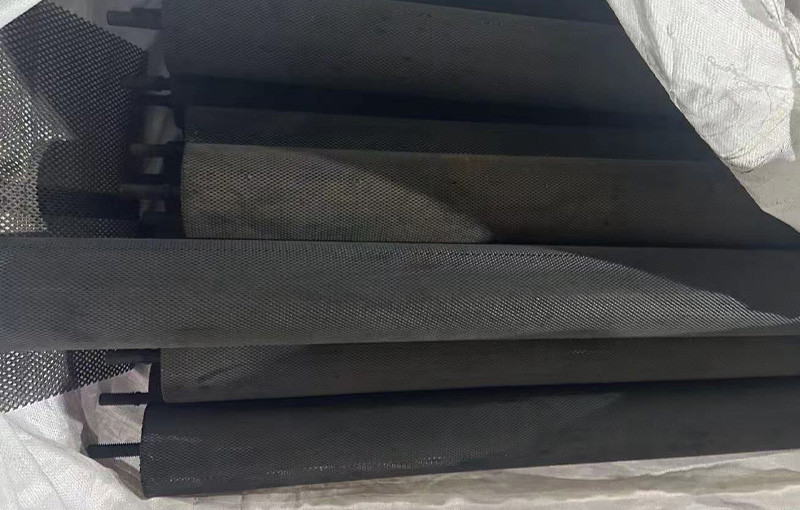

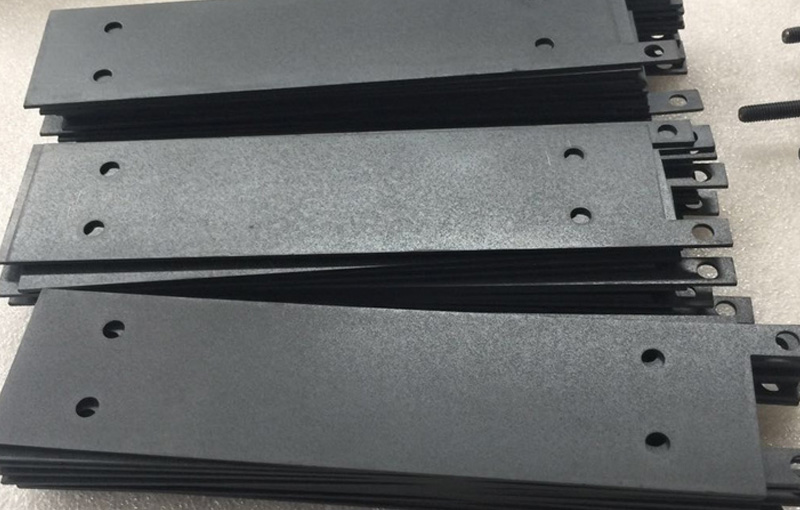

Industrial waste from the water treatment industry is dominated by metal supports of membrane modules and sludge containing heavy metals. The Industrial waste treatment technology is generally through pyrolysis or hydrometallurgy to extract iron, aluminum and other metals, used for building materials or industrial raw materials. Industrial waste treatment in Membrane module recycling is to separate the metal bracket from the polymer membrane material to realize metal reuse.

The main industrial solid waste types are titanium alloy trimmings and nickel-based high temperature alloy scrap. Industrial waste treatment plants convert titanium shavings into 3D printing powder through cold shaping or plasma atomization technology, with a material utilization rate of up to 95%. Nickel-based alloy scrap needs to be industrial solid waste treatment plant's melted and purified before it can be used in aero-engine component manufacturing.

This industry is dominated by industrial solid waste processing, and the types of scrap metal materials include: nickel-cobalt-manganese materials from power batteries, hull steel, and aluminum alloy components. Hydrometallurgy in industrial waste treatment plant extracts nickel and cobalt from lithium ternary batteries for use in the production of new batteries, reducing reliance on primary minerals. Electric arc furnace melting scrap is used to process ship hull steel for recycling, and carbon emissions from scrap recycling are 70% lower than conventional steelmaking.

Industrial solid waste processing in this sector includes: stainless steel surgical instruments, titanium implants, and nickel-based liners for reactors. High purity titanium scrap can still be used for implants such as artificial joints after smelting. Nickel-based corrosion-resistant components are recycled for use in hydrogen energy storage tanks or electrolyzer manufacturing.