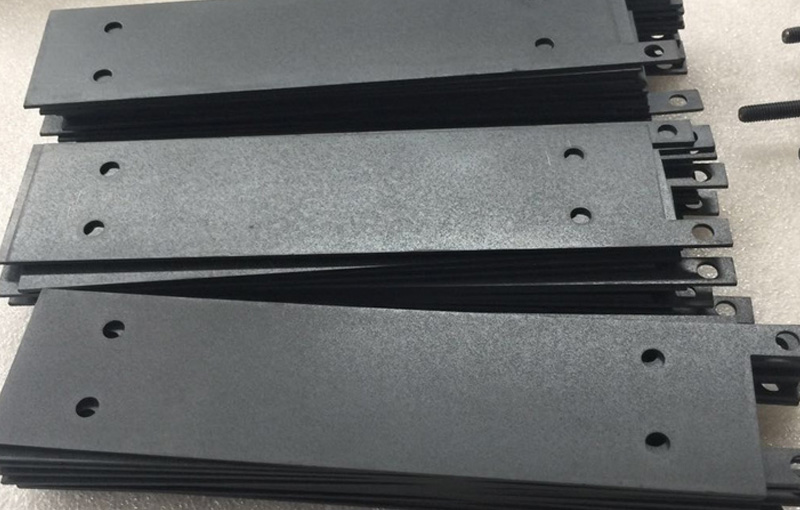

Anodes for corrosion protection using active metal properties can effectively protect steel products working in the ocean, preventing steel products from being corroded by seawater! yacht with sacrificial anodes and sacred anode boat are anode corrosion yacht with sacrificial anodes and sacrificial anode boat are the places where anode corrosion protection is used. In addition, all ocean-going vessels (including but not limited to hulls, bathyscaphe boxes, thruster tunnels and other components that need to be in contact with seawater for a long time), offshore platforms, offshore pipelines, wharves, piers, jetty strengths and jetties, etc. all need to use anodes for corrosion protection. Since seawater is highly corrosive, anodic corrosion protection products should be of good quality and conform to ISO 9001 certification.

The Interaction Between Cathode and Anode

Through the above, we can basically understand that anode corrosion protection is to protect the cathode by sacrificing the anode, so as to achieve the purpose of protecting the cathode. anode protection corrosion commonly used active metal after oxidation, effectively protects the steel structure, protects the environment, prolongs the service life of the steel structure, and reduces carbon emissions! In the industrial production of hydrogen energy, in addition to industrial scrap metal recycling, anodic corrosion protection is also an indispensable link.