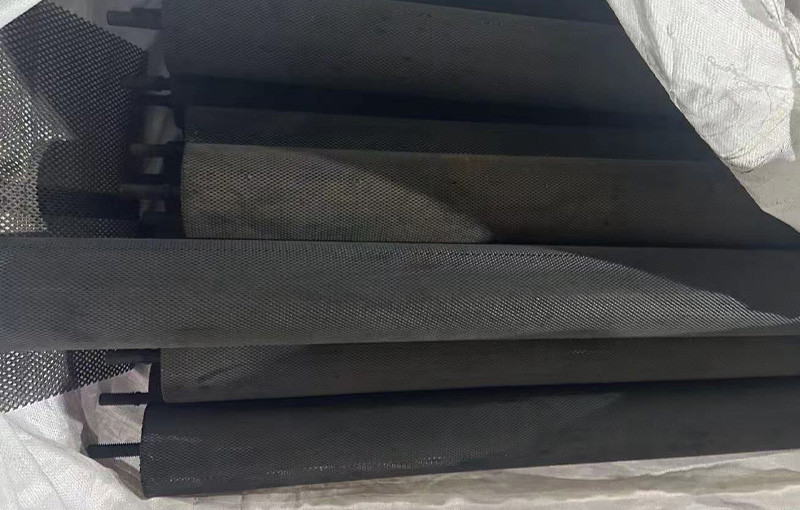

Nickel mesh is one of the basic materials for making anode oxidation materials and electrode reduction materials. In the nickel mesh recycling market, the black nickel mesh electrode used in chlor-alkali industry, water treatment, hydrometallurgy, and electrolytic synthesis is the most popular. Next is the nickel mesh electrode used for electrochemical electrode catalysis, nuclear power plant cooling water systems, and thermoelectric material metallization.

Learn about Nickel Screen Recycling

A nickel mesh electrode is made by covering nickel wire mesh with different black metal oxides on its surface, based on different production needs. Nickel mesh electrodes focus more on reduction stability and controlling the electron interface. They are suitable for environments with high voltage differences and complex mediums.

1. For cathodic protection in offshore platforms and nuclear power plant cooling water systems, nickel mesh electrodes can stop hydrogen embrittlement and withstand high salt levels and acidic environments.

2. When metallizing thermoelectric materials, nickel mesh electrodes can effectively prevent cracking at high temperatures, improving the reliability of thermoelectric devices.

3. Nickel mesh electrodes can efficiently create hydrogen peroxide to break down organic pollutants. This allows for deep sewage treatment and turning sludge into a resource.

Nickel mesh (non-electroplated nickel mesh) is very valuable for recycling. The international nickel price is about $16,897 per ton. If the recycling price offered by the customer is fair, DONGSHENG precious metal recycler is very happy to recycle nickel mesh. Usually, the recycling price for nickel mesh is 80% of the international market price. Considering shipping and recycling costs, the recycling price might be lower.

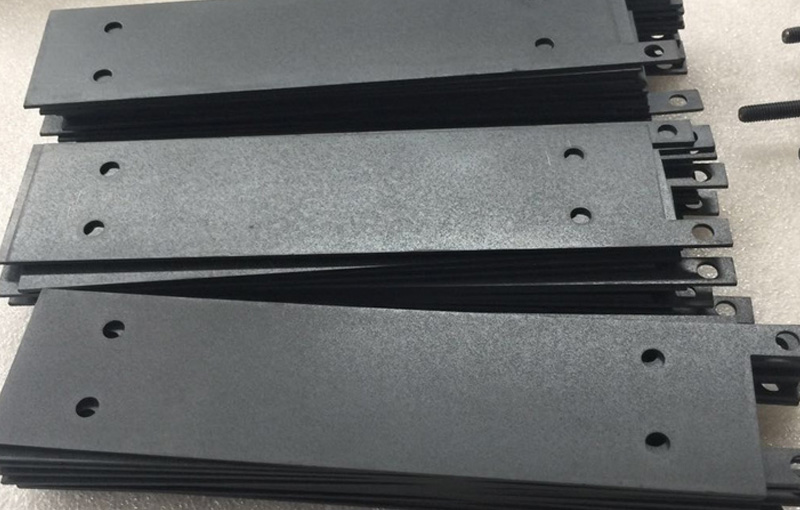

1. Plain weave nickel mesh: Smooth surface, good for high-precision filtering.

2. Twill weave nickel mesh: More flexible, high tensile strength.

3. Dense weave nickel mesh: Double-layer weave, high density, used for catalysts and battery materials.

4. Diamond hole nickel expanded mesh: Good light and air flow, often used for guardrails and decoration.

5. Hexagonal hole nickel expanded mesh: Honeycomb structure, lightweight, high strength, used in aerospace.