The global printed circuit board recycling market is experiencing steady growth. According to statistics from QYR (Hengzhou Bozhih), the global PCB e-waste recycling market reached $646 million in sales in 2024 and is projected to grow to $1.064 billion by 2031, with a compound annual growth rate (CAGR) of 7.5% (2025-2031). Regional market distribution shows distinct variations: Europe and North America have established mature recycling systems due to stringent and early-implemented environmental regulations. In contrast, the Asian market, represented by China and Japan, is rapidly expanding recycling capacity and advancing technological capabilities.

The global printed circuit board recycling market is dominated by several major players. Boliden, Umicore, and Aurubis collectively hold over 38% market share, forming the industry's first tier. These companies possess comprehensive recycling supply chains and advanced technologies, enabling efficient extraction of valuable materials such as precious metals and copper from waste circuit boards. The second tier includes companies like Mitsubishi Materials Corporation, Glencore, and DONGSHEGN precious metal recycling, which hold competitive advantages in specific regions or technological domains.

Printed Circuit Board Recycling

The European Union's Waste Electrical and Electronic Equipment Directive (WEEE Directive) is one of the most significant regulations impacting global printed circuit board recycling. According to the latest 2025 revision, the minimum recycling rate for circuit boards must reach 85%, with at least 50% of materials being reused or recycled. This necessitates Printed Circuit Board manufacturers and electronics producers to optimize material selection, enhance Printed Circuit Board disassembly feasibility, and facilitate efficient precious metal recycling.

The WEEE Directive also strengthens restrictions on hazardous substances. While the Restriction of Hazardous Substances (RoHS) Directive already limits harmful elements like lead (Pb), cadmium (Cd), and mercury (Hg), the 2025 revision further narrows the permissible scope of hazardous substances and mandates stricter traceability management by manufacturers. Additionally, WEEE mandates manufacturers to submit comprehensive Life Cycle Assessment (LCA) reports demonstrating that their PCB materials pose no long-term environmental hazards.

The Extended Producer Responsibility (EPR) system will be further strengthened in 2025. Manufacturers must prepay electronic waste disposal fees upon product launch to support national recycling systems; establish reverse logistics systems ensuring consumers can conveniently return end-of-life electronic devices; and face higher environmental taxes and market access restrictions if recycling targets are missed.

While North America lacks unified federal regulations, individual states maintain their own e-waste management laws. California's Electronic Waste Recycling Act and New York's Electronic Equipment Management and Recycling Act both impose recycling responsibilities on manufacturers and establish specific recovery rate targets. These regulations require printed circuit board recyclers to obtain environmental permits and strictly adhere to hazardous waste disposal regulations.

At the operational level, the 2025 WEEE directive mandates that all compliant circuit boards bear the “crossed-out wheeled bin” symbol and include a Digital Tracking Code (DTC). This enables regulatory authorities to track products throughout their entire lifecycle-from production and sales to usage and recycling. This change enhances transparency in e-waste flows while driving enterprises to adopt technologies like blockchain in supply chain management, thereby improving the traceability of recycling data.

The mechanical-physical method is currently the most widely adopted technology for printed circuit board recycling, first industrialized by Germany's SiCon GmbH in the 1990s. This technology achieves efficient separation of metals and non-metals through multi-stage crushing and sorting. The specific process includes: First, using a roller-type twin-shaft shredder to shred circuit boards into 3-5 cm particles; followed by further reduction to 0.5-1 cm particles using combined hammer milling technology; finally, a disc mill integrated with a water-cooling system processes the material into 30-80 mesh powder. The sorting stage employs a three-stage combined process of air classification, density separation, and high-voltage electrostatic separation to progressively isolate metals from resin fiber powder. Based on actual production data, this technology achieves copper recovery rates ≥99% with non-metallic powder copper content <1%. The advantages of mechanical-physical methods lie in their relatively simple process, scalability, minimal secondary pollution, low energy consumption, cost-effectiveness, and high separation efficiency, meeting environmental and resource recovery requirements. However, limitations include incomplete separation of metals due to overlapping physical properties and significant upfront equipment investment.

Pyrometallurgical technology extracts metals from PCBs using high temperatures, particularly suited for recovering base metals like copper and tin. This method involves heating materials to 1400-1600°C in a reverberatory furnace, where carbon reduction converts metal oxides into metallic forms. Key chemical reactions include:

2MO + C → 2M + CO₂

SnO₂ + 2C → Sn + 2CO

Subsequent processing involves adding sulfur to remove copper impurities, forming copper monosulfide (CuS) as slag for removal, followed by adjusting the tin-lead ratio to meet specifications. Although pyrometallurgical techniques offer high efficiency in Printed Circuit Board recycling, they may release harmful gases and produce hazardous byproducts, necessitating stringent gas emission control systems. This technology is primarily suited for large-scale recycling operations, involving higher equipment investment and operational costs, yet demonstrating strong adaptability to raw materials and the ability to process various types of printed circuit boards.

Pyrometallurgical technology selectively dissolves and recovers metals from Printed Circuit Boards using chemical solutions, developed and refined by the U.S. Bureau of Mines in the 1970s. The process primarily involves chemical leaching (using sodium cyanide solutions to recover gold plating or acid solutions to dissolve metals), precipitation, electrolysis, and ion exchange. Hydrometallurgy offers high metal recovery rates and excellent selectivity in PCB recycling, capable of processing low-grade metal feedstocks. However, challenges include the use of potentially toxic chemicals and stringent waste treatment protocols to prevent secondary pollution. Modern hydrometallurgical techniques have advanced to employ acidic etching solutions for copper recovery from waste Printed Circuit Boards, adjusting pH to precipitate copper ions as copper hydroxide for further processing. While chemical methods offer high efficiency and broad applicability (handling multiple metals), they generate significant pollution (cyanide toxicity, acid treatment requirements) and entail high reagent costs.

Biotechnological recovery is an emerging eco-friendly technique that selectively extracts metals from Printed Circuit Boards using microorganisms or enzymes. This method was first proposed and experimentally validated by a research team at the University of Birmingham in the early 2010s. Biotechnology employs microbial metabolites (such as organic acids and enzymes from bacteria like Ferriportichlorobacterium) to dissolve metals for subsequent separation. This PCB recycling method is environmentally friendly and energy-efficient, offering potential for selective metal recovery. However, it involves long processing times (days to weeks) and low efficiency (suitable only for low-grade metals). Biotechnological recovery is currently primarily in the R&D phase with limited industrial-scale application. It is mainly suitable for small-scale recycling with low pollution requirements or as an auxiliary method to chemical processes for pollution reduction. Despite its limitations, biotechnology represents one of the future development directions for printed circuit board recycling. With advances in biotechnology, commercial application cases are expected to emerge within the next five to ten years.

- A Summary of the Most Advanced PCB Gold Recovery Technologie

- Advanced Waste Printed Circuit Board PCB Recycling Technique

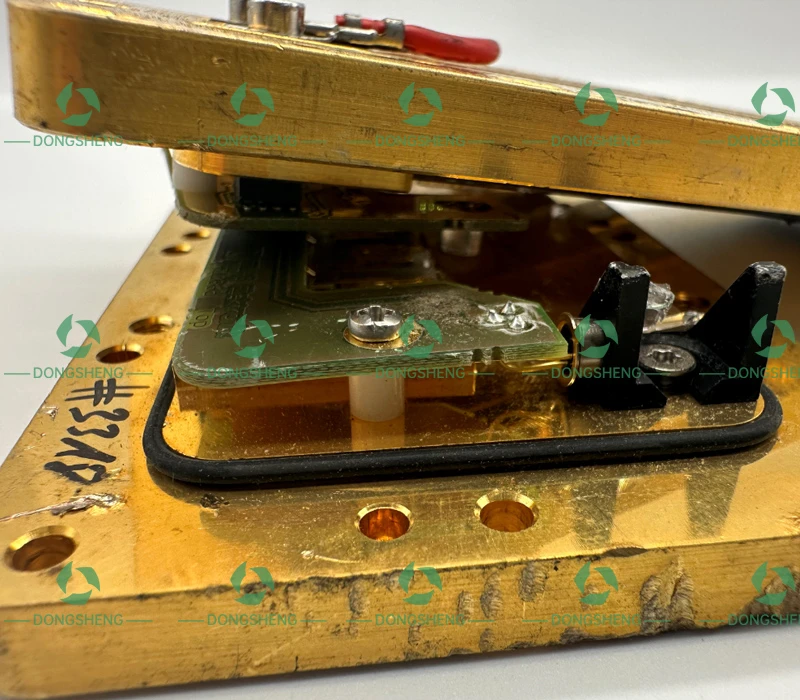

Determining precious metal content is the first step in DONGSHENG's printed circuit board recycling process. Our company employs X-ray fluorescence (XRF) analyzers for rapid testing of incoming Printed Circuit Boards, assessing approximate precious metal content based on board type, age, and source equipment. Consumer electronics circuit boards (e.g., mobile phone motherboards) typically contain higher proportions of precious metals. Industrial circuit boards (e.g., inverter boards) and automotive circuit boards (e.g., ECU boards) feature thicker copper layers due to stringent reliability requirements. Multilayer boards possess higher precious metal content and recycling value compared to single-layer or double-layer boards. Based on inspection results, DONGSHENG categorizes PCBs into three grades: Grade A (high-frequency boards, server boards, precious metal content >3%), Grade B (computer motherboards, communication boards, precious metal content 1-3%), and Grade C (home appliance boards, consumer electronics boards, precious metal content <1%). This grading determines subsequent recycling processes and quotation standards.

The direct payment and containerization process is based on the precious metal content assessment. DONGSHENG determines a base quote using the London Metal Exchange price on the day, factoring in metal recovery rates and refining costs. After payment, materials are loaded into dedicated containers with RFID tags affixed. The entire transportation process is tracked in real-time via a blockchain platform, ensuring transparent material sourcing and compliance. This direct payment model significantly streamlines transactions, gaining popularity among small and medium-sized e-waste recyclers in Europe and America. It enables them to rapidly convert collected PCBs into cash flow without investing in costly processing equipment.

The pre-treatment stage is a critical component of DONGSHENG's Printed Circuit Board recycling process. Our company employs automated systems for disassembly, using robotic arms and hot air guns to remove electronic components (capacitors, resistors, chips) from circuit boards. These components are recycled separately (some can be refurbished for reuse or further metal extraction). Next comes paint stripping: Printed Circuit Board fragments are immersed in a 10% sodium hydroxide solution with 0.5% Additive A, 0.5% Additive B, and 0.05% corrosion inhibitor thiophenylbenzotriazole. Heated in a water bath, this process completely removes surface paint within 30 minutes, fully exposing metals for recovery. The efficiency of the pretreatment stage directly impacts the efficiency and purity of subsequent metal recovery. DONGSHENG has reduced pretreatment time by 40% through automated equipment, significantly improving efficiency compared to traditional manual operations.

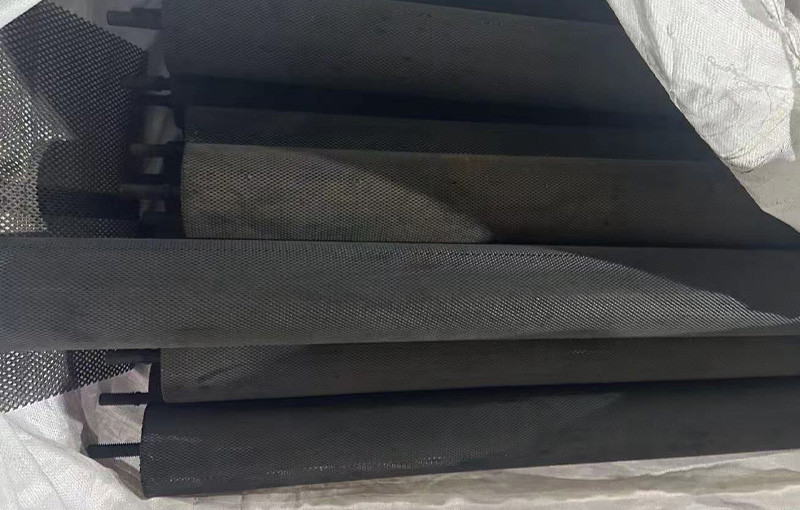

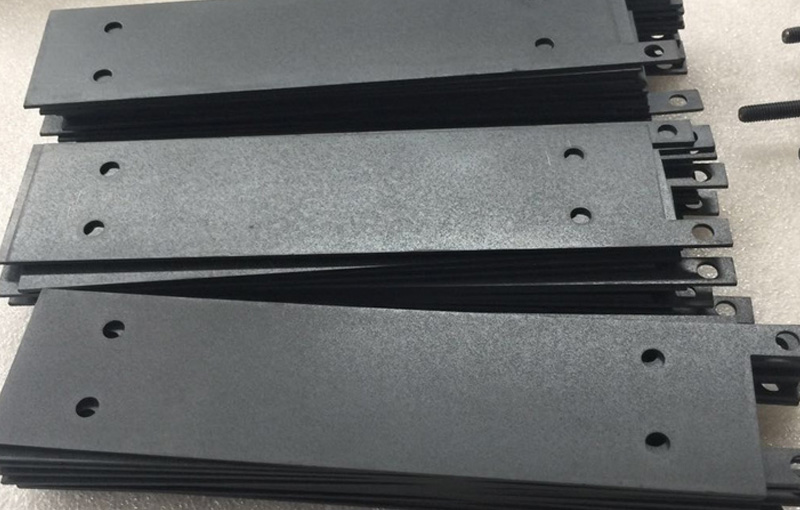

The mechanical separation process utilizes an automated system designed by GreenJet Environmental Machinery Co., Ltd. This process includes three stages of crushing: Primary crushing employs a roller-type dual-shaft shredder to reduce circuit boards into 3-5 cm particles; Secondary crushing employs hammer mill technology to refine particles to 0.5-1 cm; Tertiary pulverization uses a disc mill with water cooling to produce 30-80 mesh powder. Sorting utilizes a three-stage process combining air classification, density separation, and high-voltage electrostatic separation to progressively separate metals from resin fibers and powder. The entire system is PLC-controlled, enabling automatic/manual operation switching. It features a human-machine interface screen to ensure stable operation and convenient maintenance. DONGSHENG's practice demonstrates that this mechanical separation process achieves copper recovery rates ≥99%, non-metallic powder copper content <1%, and hourly processing capacities of 600-800 kg, significantly enhancing printed circuit board recycling efficiency.

During the precious metal extraction and refining stage, DONGSHENG employs different technical approaches based on the grade of printed circuit boards. For Grade A high-value boards, physical methods such as vacuum distillation and zone melting are utilized. These leverage the differences in boiling points and melting points of various metals, separating them through heating (e.g., copper has a higher boiling point than gold, so gold vaporizes and condenses first during distillation). Though energy-intensive and costly in equipment, this method is environmentally friendly (no chemical reagents) and achieves high purity (up to 99.99%). For Grade B and C boards, hydrometallurgical techniques are employed, such as cyanidation to dissolve gold into gold-cyanide complexes, followed by gold extraction using zinc powder. Extracted precious metals undergo electrolytic refining to achieve over 99.95% purity before being cast into ingots for customer delivery. All three wastes (effluent, exhaust gases, residues) generated throughout the process undergo rigorous treatment: wastewater is neutralized with acids/alkalis to precipitate heavy metals; exhaust gases are collected and acid gases absorbed with alkaline solutions; residues containing residual heavy metals are solidified and stabilized before disposal at hazardous waste treatment centers.

- Latest Printed Circuit Board Recycling Technologies and Prices

- What are the key features of the best Printed circuit board

- Printed Circuit Board Recycling Methods

Through this comprehensive process, DONGSHENG achieves efficient and resource-oriented printed circuit board recycling, maximizing the recovery of valuable materials while ensuring environmental compliance. The company's experience demonstrates that successful PCB recycling requires balancing technical efficiency, economic costs, and environmental requirements. By optimizing processes and adopting advanced technologies, it is possible to achieve a win-win outcome for both economic and environmental benefits.

Table: Output Metrics for Each Stage of DONGSHENG's Printed Circuit Board Recycling Process

| Processing Stage | Metal Recovery Rate (%) | Processing Capacity (kg/h) | Energy Consumption (kWh/kg) | Byproduct Utilization Rate (%) |

| Preprocessing | - | 800 | 0.15 | 95 |

| Mechanical separation | 99 | 600 | 0.25 | 98 |

| Hydrometallurgy | 98.5 | 400 | 0.35 | 90 |

| Pyrometallurgy | 99.5 | 1000 | 0.45 | 85 |