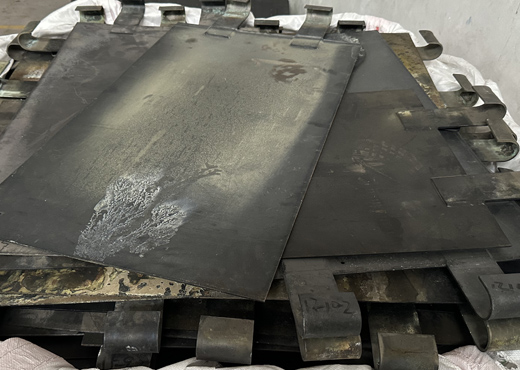

The core target of titanium scrap recycling covers titanium-containing materials from industrial processing and end-of-life, of which titanium mesh and titanium plate are the main forms. Titanium plate scrap mainly originates from aerospace structural components (such as engine mounts, bulkhead liners) and chemical electrolysis tank cathode plates, which are characterized by large area and clear alloy composition (TC4, Gr.2 pure titanium is the main one), but are often composite plating or bonding materials. Titanium mesh scrap is concentrated in the chemical filtration system and pharmaceutical separation equipment, due to long-term contact with acidic media to form a thickened oxide layer, and the structure is easy to deform. 2025 a U.S. space base auction of 15 tons of titanium alloy scrap, TC4 accounted for more than 70% of the interspersed with TC21 and traces of aluminum, steel impurities, the need for on-site inspection to assess the proportion of oil and inclusions. This kind of mixed titanium scrap directly determines the difficulty of titanium scrap recycling pretreatment and regeneration value stratification.

DONGSHENG's recycled titanium scrap is mainly used as cathodes and anodes in industrial production. In the recycling of titanium scrap with coating, DONGSHENG has a huge technical advantage, which is the reason why we can give competitive price for titanium scrap recycling.

See what we recycle in titanium mesh and plate: titanium mesh recycling, titanium plate recycling;

To get a rough idea of prices you can read these three pages:

1, Titanium scrap prices.

2, How much is titanium scrap worth?

3, Top Titanium Recycling Technology and Prices.

For an accurate price please contact us!

Titanium mesh recycling and titanium plate recycling need to be targeted to break the technical bottleneck. The difficulty of titanium plate recycling lies in the stripping of coating: for example, the titanium-based lead dioxide anode plate for electrolysis, the traditional incineration method is highly polluting and the titanium substrate is damaged.DONGSHENG titanium scrap recycling department uses electrochemical deprocessing technology to strip the lead dioxide layer in 6 hours by combining nitric acid electrolyte with ultrasonic stirring, the titanium plate recycling rate is up to 92%, and the recycling substrate can be electrodeposited with the functional coating again. The recycling of titanium mesh focuses on deoxidizing and controlling impurities: the crushed titanium mesh is powdered by argon atomization, and the oxygen content needs to be pressed down to less than 0.13% in order to meet the requirements of additive manufacturing. The French EcoTitanium factory remelted Airbus engine hanger titanium scrap into titanium ingots containing 75% recycled material, which were used for A350 fuselage parts, verifying the feasibility of recycling aviation-grade titanium plates. And the U.S. IperionX patented technology to directly process high-oxygen titanium mesh scrap, output in line with ASTM F3001 standard 3D printing titanium powder, used by the Navy for ship pump body manufacturing.

The recycling of titanium scrap has formed a closed-loop chain of military-aviation-chemical industry. In the field of aviation, EcoTitanium recycles titanium plate scrap into recycled titanium ingot, which reduces energy consumption by 75% compared with titanium sponge and is used for Airbus A350 fuselage load bearing parts.In the field of 3D printing, IperionX regenerated titanium powder is used to manufacture military pump body through SLM 280 equipment, which shortens the maintenance cycle of the ship by 40%. In the field of chemical industry, DONGSHENG titanium scrap recycling factory adopts the regeneration process of titanium mesh lead dioxide anode plate: the titanium mesh obtained by deprocessing is recoated with active layer after sand blasting and pickling, the regenerated anode tank voltage is reduced by 12%, and the service life is equivalent to the new product. The current limitation lies in the insufficient coverage of the titanium scrap recycling collection network - the European aviation titanium closed loop only meets 25% of the demand, and requires the expansion of dismantling centers and intelligent sorting technology investment.

> The ultimate goal of titanium scrap recycling is not to replace virgin ore, but to establish an industrial metabolism system in which ŌĆ£titanium scrap is a resourceŌĆØ.

>Military-grade titanium plate recycling and pharmaceutical-grade titanium mesh recycling are indispensable links in the toughness of modern industry.

3, DSA Anode

4, MMO Anode

5, Coated Titanium Anodes for Aerospace

6, High Price Titanium Alloy Recycling Company

7, Recycling of Seawater Electrolysis AEM Electrolyzer Parts