Get Inquiry

Send an inquiry and get in touch

Confirming the Transaction

Video photos, confirm transaction

Acceptance of Transportation

On site acceptance, packing and transportation

Sorting Processing

Sort materials and process them by category

Grinding and Decomposition

Physical grinding, chemical decomposition

Purification and Recovery

Purification of materials, completion of recycling

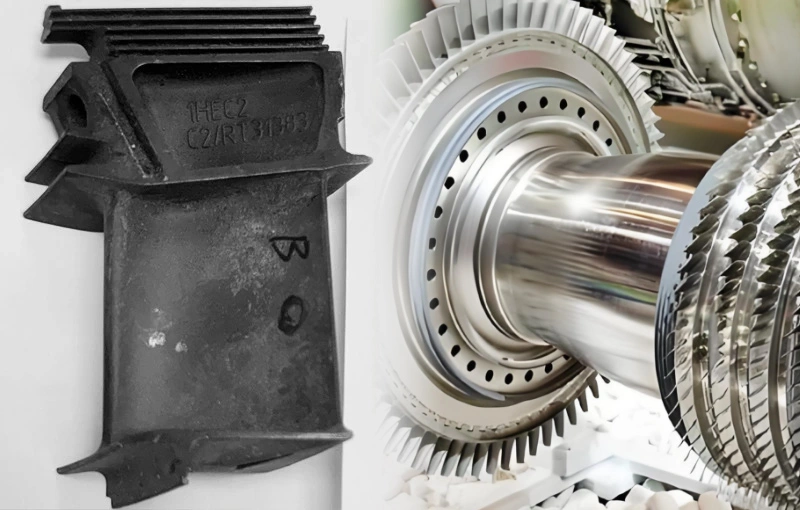

Other High Temperature Alloy

Microstructural control is paramount for high temperature alloys. The size, morphology, and distribution of the γ' phase in high temperature, high-strength nickel-based alloys directly influence the material's high temperature creep resistance and fatigue strength.

Processing these alloys presents significant challenges. The latest “progressive reset” annealing technique effectively eliminates localized stress concentrations from casting, reducing dislocation density in deformed regions from 2.62×10¹⁴ m⁻² to 1.45×10¹⁴ m⁻² and suppressing recrystallization defects.

High-temperature alloys are rich in precious metals and have extremely high recycling value in the field of precious metal recycling. Among them, nickel-based high-temperature alloys and nickel-based high-temperature alloy turbine blades are the most popular recycled materials in the aerospace field.

Cobalt-based high temperature alloys occupy a unique position in the field due to their exceptional thermal corrosion resistance and high temperature fatigue strength. These materials feature a cobalt matrix typically alloyed with elements like chromium and tungsten, exhibiting outstanding microstructural stability under elevated temperatures.

Compared to nickel-based high temperature alloys, cobalt-based alloys possess higher solidus temperatures and superior thermal corrosion resistance, making them particularly suitable for stationary components operating long-term in high temperature corrosive environments.

Guide vanes and combustion chamber components in gas turbines represent typical applications for cobalt-based high temperature alloys, as these parts endure direct impact from high temperature combustion gases.

In practical engineering applications, cobalt-based high temperature alloys demonstrate outstanding thermal fatigue resistance, withstanding thermal stress fluctuations from frequent start-stop cycles. These materials are also commonly used in engine sealing rings and fasteners, where their thermal expansion coefficient matches well with nickel-based high temperature alloy components, ensuring stable fit relationships across wide temperature ranges.

High temperature nickel alloy springs serve as core components in pressure control and sealing systems under extreme conditions, widely deployed in aeroengines, petrochemical plants, and energy equipment. These spring elements maintain stable elastic properties at temperatures up to 650°C, where conventional spring steel exhibits significant relaxation.

In aircraft engine control systems and chemical valves, high temperature nickel alloy springs deliver sustained, consistent contact pressure, ensuring reliable sealing under high temperature conditions.

Unlike conventional springs, high temperature nickel alloy springs must operate long-term under high temperatures and sustained stress, making creep resistance a critical performance metric.

Representative high temperature nickel alloys like Alloy X/2.4656 maintain tensile strengths exceeding 250 MPa at 800°C, providing ample strength reserves for high temperature spring design.

In practical applications, engineers must specifically account for the work-hardening characteristics of high temperature nickel alloy springs. Appropriate heat treatment processes are employed to adjust the material's elastic modulus and fatigue strength.

Manufacturing these springs involves precise coiling techniques and stringent heat treatment control to ensure stable mechanical properties under elevated temperatures.

High temperature nickel alloy strip serves as a critical material across diverse industrial sectors due to its excellent formability and high temperature strength. This thin sheet material can be fabricated into complex components through processes like stamping, bending, and welding to meet high temperature application requirements.

In aerospace applications, high temperature nickel alloy strip is commonly used for combustion chamber assemblies and heat exchanger components. Nickel-chromium-iron-molybdenum alloy strips, exemplified by HASTELLOY X, achieve tensile strengths up to 784 MPa and elongation of 45% in the solution-treated state, combining excellent formability with superior high temperature performance.

Controlling strain hardening effects is critical during the actual processing of high temperature nickel alloy strip. Intermediate annealing restores material plasticity, enabling the strip to undergo multiple deformations without cracking.

During welding, composition-matched filler metals must be selected. Post-weld heat treatment restores corrosion resistance in the weld zone.

In the energy sector, high temperature nickel alloy strip is fabricated into gas turbine transition sections and sealing components. Within the chemical industry, this material is processed into linings for reaction vessels and heat exchanger tubes.

These applications fully leverage the high temperature nickel alloy strip's strength advantages and corrosion resistance at elevated temperatures, ensuring long-term stable operation of equipment in demanding environments.