When electrified, the cathode zone of industrial circulating water treatment titanium mesh creates a high-pH environment (>9.5), causing calcium/magnesium ions to precipitate as calcium carbonate scale in advance. This reduces pipeline scaling. For water purification, the mesh balances mineral content via electrolysis, inhibits rust formation, adsorbs heavy metal ions for deposition in reaction chambers, and extends the lifespan of cooling towers and condensers. It is widely used in seawater cooling systems for chemical plants.

This titanium mesh also treats landfill leachate and oilfield wastewater, efficiently degrading organic pollutants (e.g., petroleum-based contaminants). Modular system integration further reduces overall costs.

Base material: High-purity titanium (Ōēź99.7%)

Efficiency: Current efficiency >80%, cell voltage <5.0V

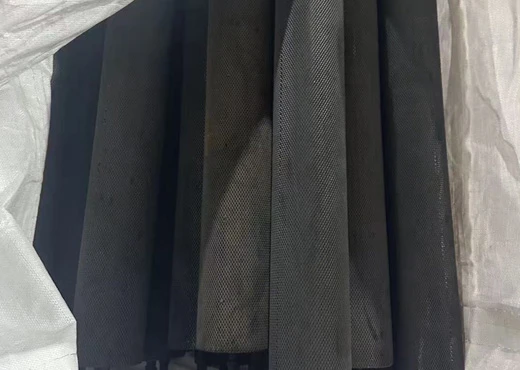

Mesh pattern: Expanded mesh (diamond-shaped openings: 0.5├Ś1.0mm to 1.5├Ś3.0mm)

Modularity: Supports multi-stage cylindrical assembly; individual modules allow independent replacement/maintenance