In 2025, breakthrough progress was achieved in printed circuit board recycling technology. A joint research team from the University of Maryland, Georgia Institute of Technology, and the University of Notre Dame developed an innovative technology named "DissolvPCB" This printed circuit board utilizes polyvinyl alcohol (PVA) as a water-soluble substrate and gallium-indium eutectic alloy (EGaIn) as the conductive material.

When the Printed Circuit Boards becomes obsolete, simply immersing it in water causes the PVA substrate to dissolve. The liquid metal then re-aggregates into bead-like structures, while electronic components are completely separated. This process achieves a material recovery rate exceeding 98%.

This Printed Circuit Board recycling method significantly simplifies the recovery process, offering convenience for small laboratories and maker spaces. Regarding pricing, standard low-metal-content Printed Circuit Board typically fetch $0.22ŌĆō0.25/kg, while multilayer boards can reach $0.70ŌĆō0.90/kg. High-value precious-metal Printed Circuit Board command prices as high as $5ŌĆō10/kg.

The above Printed Circuit Board recycling prices are for reference only. For precise quotations, please contact our procurement specialists.

The traditional printed circuit board recycling process typically involves several key stages. First, components must be removed and solder separated. One method involves immersing the entire board in a heating medium (such as diesel or silicone oil) at 220┬░C-300┬░C to melt the solder, which is then recovered through centrifugal separation.

Next comes the crushing stage, where shear crushers reduce the boards to 5-20mm fragments, followed by further grinding to completely separate metals from non-metals.

This is followed by sorting, where the separated mixed material is processed through pneumatic or electrostatic separators to yield copper powder, gold powder, and non-metallic powders. Some advanced processes employ vacuum pyrolysis technology to pre-treat printed circuit boards, separating and recovering organic components before crushing.

The economic value of printed circuit board recycling is primarily determined by its precious metal content, which far exceeds that of natural ores.

Data indicates that discarded Printed Circuit Board contain 100-200 grams of golden per ton, whereas the world's richest gold ore deposits yield only 5-10 grams per ton. High-end Printed Circuit Board also contain valuable metals like silver, palladium, and platinum.

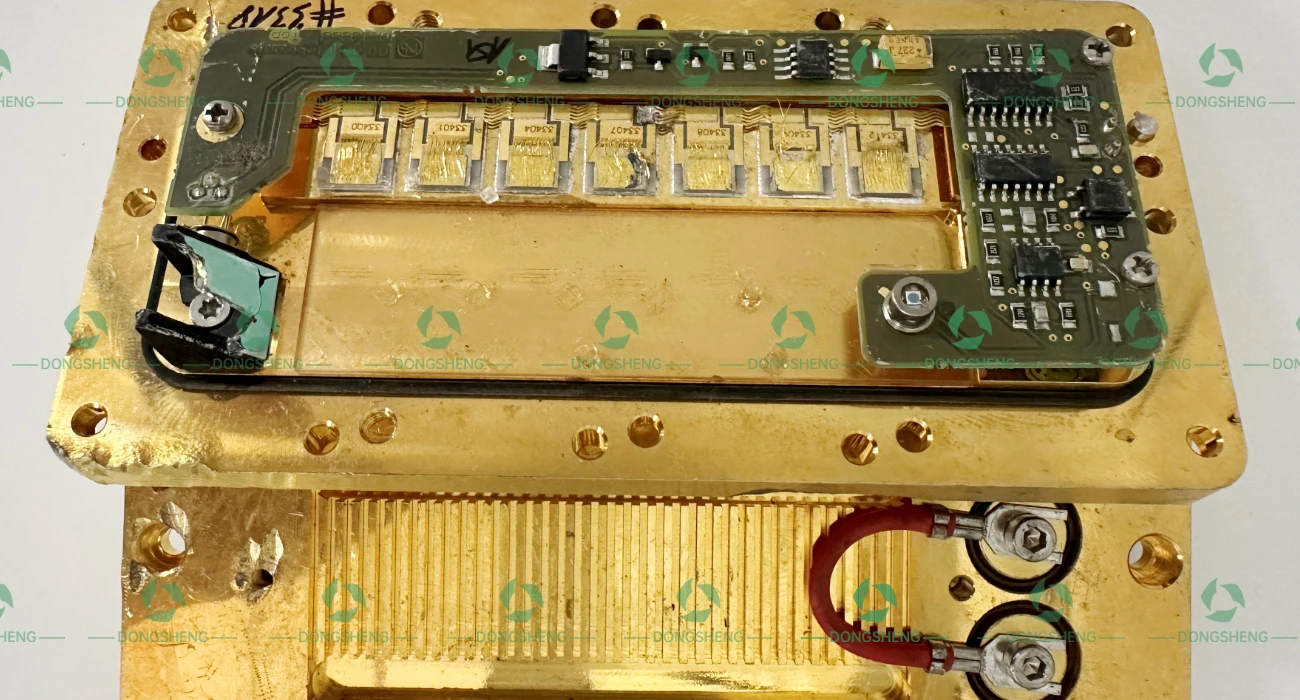

Printed Circuit Board recyclers typically categorize boards into three types: standard single-layer/ double-layer boards (2%-5% metal content, recycling price approx. $0.22-$0.25/kg), multi-layer boards (10%-15% metal content, recycling price approx. $0.7-$0.9/kg), and high-value boards (over 20% metal content, including gold plating, recycling price approx. $5-$10/kg).

Precious metal recyclers usually conduct sample analysis to determine exact precious metal content before quoting prices.

Experienced PCB recycling facilities have observed that older industrial electronic Gold Printed Circuit Board often command higher recycling values. Printed Circuit Board used in legacy industrial equipment, military hardware, and telecommunications devices typically feature thick copper plating and contain more precious metal connectors and gold-plated pins.

Statistics indicate that despite advancements in processing technology and reduced costs, approximately 180 grams of gold can still be recovered per ton of waste circuit boards. Older Printed Circuit Board, featuring simpler designs, also facilitate easier component disassembly and sorting, thereby lowering overall recycling costs.